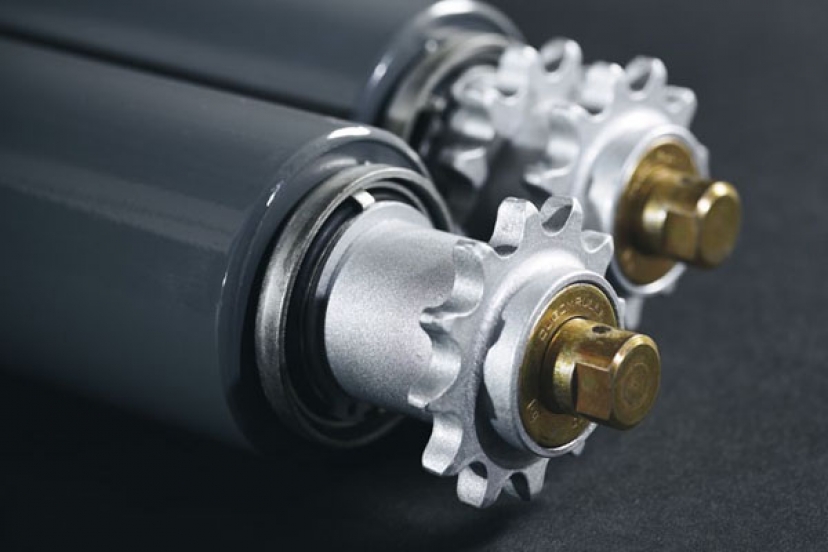

Medium and heavy duty chain driven friction rollers

Downloads

- 01C - Technical information - the Rollers

- 02C - Technical information - applications and design criteria

- 25C - Series 333 Rollers - Description and operating characteristics